Partnering for integrated furnace offerings

IMPROVED INSIGHTS Clients of both DGC and Hotwork will soon benefit from improved traceability, predictive data insights and accelerated decision-making capabilities during mission-critical operations

AI IMPLEMENTATION DGC is actively investigating the implementation of AI-driven diagnostics through ongoing collaborations

OPERATIONAL EFFICIENCY The adoption and implementation of advanced digital technologies into furnace and kiln operations has already led to marked improvements in efficiency

A strategic alliance has been formed between South African industrial services and asset integrity management specialist Dickinson Group of Companies (DGC) and Swiss advanced combustion technology service provider Hotwork International to deliver integrated solutions aimed at optimising operational performance, reducing unplanned downtime and extending the service life of high-temperature process equipment.

Hotwork International, with a service footprint that spans more than 90 countries, brings decades of experience in controlled furnace draining, furnace heat-up and cool-down, refractory dry-out and regenerator repair services.

“The company is known for its use of advanced combustion systems including low-nitrogen oxides, oxy-fuel and hydrogen-capable burners, to ensure energy efficiency, emissions compliance and precise thermal control,” says DGC business development director Justin Nothnagel.

By combining Hotwork’s expertise with DGC’s turnkey furnace and smelter services, he says the evolving needs of industrial clients in the mining, metals and heavy industrial sectors across the region can be addressed.

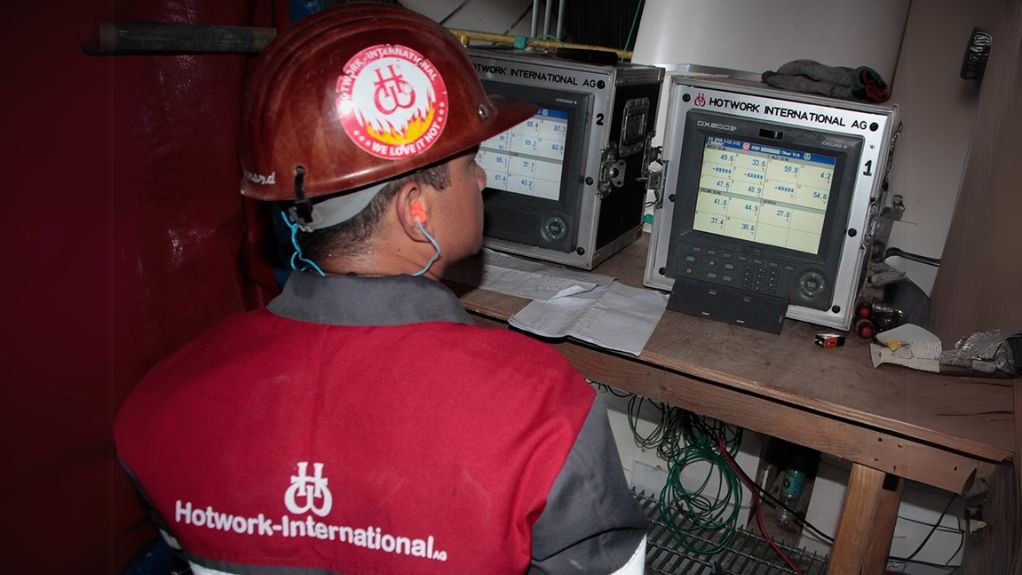

DGC and Hotwork International are also jointly rolling out a suite of digital tools that include remote temperature monitoring systems, real-time data logging and digital project dashboards. These innovations are designed to enhance operational visibility, improve precision and ensure accountability throughout the furnace maintenance lifecycle.

Clients of both DGC and Hotwork will soon benefit from improved traceability, predictive data insights and accelerated decision-making capabilities during mission-critical operations, says Nothnagel.

The adoption and integration of advanced digital technologies into furnace and kiln operations has already led to marked improvements in operational efficiency, he states.

“For instance, the use of automated temperature mapping and remote monitoring systems allows for precise control during refractory dry-out processes, potentially reducing the time required while maintaining safety and thermal ramp-up control, [while] digital planning tools contribute to improved project execution times and better resource coordination across teams,” notes Nothnagel.

Digital Tools

At present, DGC uses a combination of thermal monitoring systems, infrared thermal imaging and analytics dashboards to continuously monitor furnace performance and detect early indicators of wear or impending failure.

These systems play a central role in supporting predictive maintenance strategies that are designed to reduce the occurrence of unplanned outages while also extending the operational life of key thermal equipment.

Nothnagel recounts how DGC successfully executed comprehensive turnkey furnace refurbishment projects for two platinum group metal (PGM) producers in South Africa, saying that these projects encompassed the full spectrum of services, including refractory demolition, mechanical repairs and refractory installation.

“By leveraging advanced planning techniques and cutting-edge technology, DGC delivered high-performance, fully operational furnaces, thereby enhancing the client’s production capacities and operational efficiency,” he shares.

Another instance involved Hotwork International providing highly specialised heat-up services for blast furnace stoves, using high-velocity burners to deliver precise temperature control across a range from 60 ºC to 1 200 ºC. This technology achieved temperature uniformity, maintaining variances to within more than 3 ºC – a critical requirement for the integrity of expansion-sensitive materials such as silica brick.

Achieving this level of precision in thermal management is important for avoiding structural failures and ensuring the long-term reliability of the furnace infrastructure, notes Nothnagel.

The introduction of such advanced technologies, he adds, has also contributed to significant safety improvements during operations. “By replacing manual heat-up methods with automated control systems and implementing stringent safety protocols, we have significantly lowered the risk of thermal stress, hot spots and refractory failure.”

Implementation of AI

DGC is actively investigating the implementation of AI-driven diagnostics through ongoing collaborations with some of its other global technology partners. As such, the company is broadening its geographic reach across sub-Saharan Africa, with expanded local capabilities in South Africa, Zambia, Zimbabwe and the Democratic Republic of Congo, while also pursuing strategic growth in new international markets such as Madagascar, the United Arab Emirates and South America.

The company believes that AI will help play a transformative role in enabling remote online condition monitoring, enhancing energy-efficient thermal processes and supporting integrated maintenance strategies that combine mechanical, refractory and digital service offerings, all of which are increasingly in demand among industrial clients, notes Nothnagel.

As environmental and economic pressures continue to intensify, he points out that clients are seeking shorter turnaround times, lower emissions during furnace heat-up phases and data-backed performance validation.

In response to these changing priorities, Nothnagel says DGC is positioning the company, through the integration of local expertise with modern technology, such as in the case of the partnership with Hotwork International, to meet the evolving requirements of the African mining industry, enabling clients to enhance uptime, extend asset longevity and improve the overall safety and efficiency of their thermal operations.

“The DGC–Hotwork International partnership exemplifies our commitment to world-class thermal services,” he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation